Oct 29,2025

0

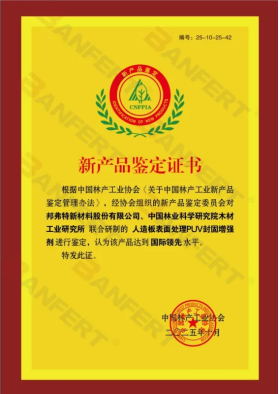

October 2025 – The "PUV Sealing and Enhancement Technology for Surface Treatment of Wood-Based Panels" and its corresponding product, the "PUV Sealing and Enhancement Agent," developed by Banfert New Materials Co., Ltd. in collaboration with the Wood Industry Research Institute of the Chinese Academy of Forestry, have been rigorously evaluated by an authoritative expert committee and officially recognized as achieving an "internationally leading level."

This milestone not only signifies a breakthrough advancement for Banfert in surface treatment technology for wood-based panels but also offers the industry a new high-performance, eco-friendly solution.

On October 25, 2025, an achievement evaluation meeting was successfully held in Changsha, Hunan. Organized by Mr. Zhou Hongsheng, President of the China Forest Products Industry Association, and Ms. Li Dongyan, Secretary-General of the association, the review committee comprised top industry experts, including Professor Yu Zhiming of Beijing Forestry University, Professor Li Xianjun of Central South University of Forestry and Technology, Researchers Lü Bin and Long Ling from the Wood Industry Research Institute of the Chinese Academy of Forestry, and Mr. Quan Qinghao, Director of the R&D Center of Shouguang Luli Wood Industry Co., Ltd.

Mr. Li Xinxiong, Chairman of Banfert, led the core R&D team to attend the meeting, alongside key researchers from the Wood Industry Research Institute. The experts conducted an on-site inspection of Banfert’s R&D laboratory, examining the technology’s development process, formula design, and product samples. Following a comprehensive presentation by the project team, the committee unanimously concluded that the technology and product demonstrated internationally leading performance in formulation design, process optimization, and functional efficacy, providing critical support for the advancement of sealing and interface enhancement technologies in wood-based panels.

Traditional surface treatments for wood-based panels often face three major challenges: poor adhesion, surface roughness, and weak finish cohesion, which compromise both durability and aesthetics. Banfert’s PUV Sealing and Enhancement Technology offers a targeted solution.

Through optimized formulation and process design, Banfert has developed a dual-component, high-penetration, high-strength PUV Sealing and Enhancement Agent. This agent deeply penetrates the substrate, undergoes UV curing to form a dense cross-linked layer, and significantly enhances surface smoothness while masking defects such as pores and cracks. The result is markedly improved adhesion between the substrate and decorative materials (e.g., films or papers), leading to substantially higher peel strength in the finish layer.

The technology offers four key advantages:

1.Deep Penetration and Excellent Masking: Ensures smooth surfaces on particleboard, MDF, and plywood, with enhanced interfacial adhesion and peel strength.

2.High Production Efficiency: Enables continuous roller-coating without post-treatment curing cycles, outperforming traditional melamine impregnation or hot-pressing methods.

3.uperior Eco-Friendliness: The PUV agent contains no free formaldehyde, heavy metals, or volatile irritants, and emits no odor during UV curing.

4.Strong Equipment Compatibility: Compatible with conventional coating and laminating machinery without modification.

Already widely adopted in the pretreatment of decorative films, papers, and finished panels, the product is becoming a new industry standard.

The PUV technology co-developed by Banfert and the Wood Industry Research Institute represents a major step forward in surface treatment innovation, providing a practical and scalable solution for industrial applications.

This breakthrough underscores Banfert’s commitment to its vision of becoming a “Global Expert in Green, High-Performance UV New Materials,” highlighting its technical prowess and capacity for innovation in UV material R&D. It is poised to drive high-quality development and industrial upgrading across the wood-based panel finishing sector.

This international recognition not only affirms Banfert’s technological capabilities but also marks the beginning of a new chapter. Banfert will continue to deepen innovation, promote industrial advancement, and contribute to the sustainable, high-quality growth of the industry.