Nov 12,2025

0

Currently, digital printing technology has broken through the limitations of traditional printing. With its excellent substrate adaptability, high production efficiency, and flexible customization capabilities, it has become a new trend in the development of the decorative materials industry. As equipment precision continues to improve and consumer aesthetic demands increasingly evolve, digital printing is driving high-end decorative materials towards higher levels of visual and tactile expression. Against this backdrop, Banfert's innovatively developed Digital 3D-UV Coating Solution has emerged. This solution endows substrates with genuine 3D tactile sensation and natural, clear visual precision, giving every inch of the surface material's texture a real, three-dimensional life.

Solution Overview:

Banfert has independently developed "UV Developer Liquid" and "UV Texture Coatings," establishing a novel "subtractive" 3D texturing technology. Simultaneously, combined with high-precision digital printing, it innovatively replicates the textures of natural wood grain, stone, etc., presenting realistic, three-dimensional textures. Paired with high-performance UV topcoats, it creates 3D digital coatings that combine visual appeal with exceptional durability, infusing modern living spaces with natural inspiration and technological charm.

Three Core Innovations:

1."Subtractive" 3D Texturing Technology

•Description: Moving away from the traditional "layer-by-layer" material application model, this technology utilizes self-developed "UV Developer Liquid" and "UV Texture Coatings" to create differential reactions during the UV curing process, selectively "carving" out textures. This innovative "subtractive" process allows for more precise and efficient replication of the profound textures found in natural wood and stone.

•Translation Note: "Subtractive" is used directly as it's a recognized technical term contrasting with "additive" manufacturing/processes. "Carving" is used metaphorically to vividly convey the selective creation of texture.

2.Differential Curing and Gradient Wire-Drawing Process

•Description:Under specific UV light conditions, the Developer Liquid and Texture Coatings exhibit different curing rates and shrinkage rates. Subsequently, through a precisely controlled wire-drawing process, realistic and natural导管凹陷 (guide tube depressions - Note: This likely refers to wood vessel pores or grain cavities. A more standard term is needed) and gradient variations are formed on the pattern. This makes the floor texture appear浑然天成 (as if naturally formed - Translation: naturally formed/integrated), introducing the lively interest of nature into living spaces.

•Translation Note: "Wire-drawing process" is a direct translation of "拉丝工艺," a specific industrial term. The Chinese phrase "导管凹陷" is interpreted and translated based on context (wood grain anatomy). "浑然天成" is idiomatically translated for natural flow.

3.Free Control of Texture Depth

•Description: Through digital control of printing and coating parameters, precise and free adjustment of texture depth and morphology can be achieved, meeting diverse design needs ranging from fine tactile sensations to pronounced three-dimensionality.

•Translation Note: "Morphology" is used as a precise term for the form/shape of the texture.

Innovation Protection: This technology has simultaneously filed for patent protection in China, the United States, and Europe.

Four Major Advantages:

1.Ultimate Aesthetics, Rivaling Nature

•Description: Utilizing synchronized patterning technology, it ensures perfect alignment between the visual pattern and the three-dimensional tactile feel. The texture realism is extremely high, replicating the premium quality of natural materials and achieving bionic effects for both vision and touch.

•Translation Note: "Synchronized patterning" conveys the idea of "同步对纹" (simultaneous pattern alignment). "Bionic" is used to translate "双重仿生," meaning imitating nature in both look and feel.

2.Design Freedom, Rapid Customization

•Description: Supports customized patterns. Various designs and patterns can be printed in one pass without the need for plates, enabling quick responses to diverse, small-batch market demands and providing designers with unlimited creative space.

•Translation Note: "Without the need for plates" clarifies the benefit of "无需制版." "One pass" printing indicates efficiency.

3.Superior Durability, Long-Lasting Beauty

•Description: Equipped with super-wear-resistant UV coatings, it endows products with exceptional wear and scratch resistance. This effectively addresses the industry pain point of traditional plastic floors being prone to scratching, significantly extending the product's lifespan.

•Translation Note: "Pain point" is a common business term for a significant problem. "Long-Lasting Beauty" captures "经久弥新."

4.High Efficiency & Environmental Friendliness, Reducing Costs & Boosting Efficiency

•Description: The process flow is significantly simplified, reducing the consumption of multiple material layers such as printed films and wear layers. This reduces inventory pressure and material costs at the source. Simultaneously, the UV coating system is environmentally friendly, aligning with green manufacturing trends.

•Translation Note: "At the source" emphasizes the fundamental nature of the cost reduction. "Aligning with" is a standard phrase for compliance with trends.

Six-Step Process Flow:

1.Base Coating / Sealing with White Base

•Description: Standardizes the base color for different substrates like PVC and wood. Depending on design requirements, roller coating of different colored base coats can be applied, providing a pure and uniform canvas for subsequent digital printing.

•Translation Note: "Sealing" is a technical term for initial coating. "Canvas" metaphorically describes the prepared surface.

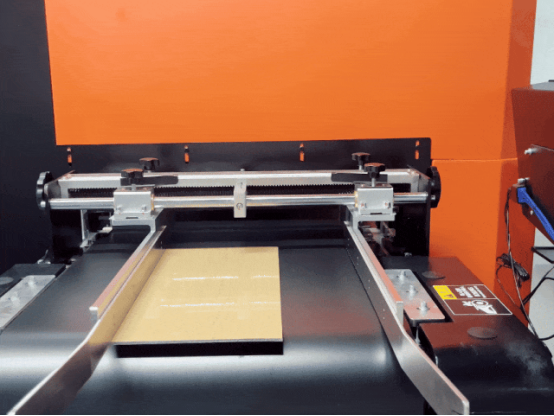

2.Digital Pattern Printing

•Description: Utilizes high-precision digital inkjet equipment to print wood grain patterns onto the substrate in one pass according to customer-specific needs, achieving precise registration and color reproduction.

•Translation Note: "Registration" is the technical term for pattern alignment.

3.Roller Coating of Wear-Resistant Texture Coating

•Description: A specially formulated wear-resistant texture coating is roller-applied onto the printed pattern, forming a sturdy "armor" for the floor or board, significantly enhancing the product's abrasion resistance and practicality.

•Translation Note: "Texture Coating" is used for "结构漆" in this context, implying it contributes to the texture build-up.

4.Printing of UV Developer Liquid

•Description: This is the core step. The self-developed UV Developer Liquid is printed onto the wear-resistant texture coating. The Developer Liquid, in conjunction with subsequent processes, is the key prerequisite for achieving synchronized patterning and the three-dimensional effect.

•Translation Note: "Prerequisite" clearly states the importance of this step.

5.Wire-Drawing and Dust Removal

•Description: Applies the gradient wire-drawing process to physically engrave realistic导管凹槽 (guide tube grooves - see note above: wood grain pores/cavities) and three-dimensional textures onto the wood grain pattern coated with the developer liquid. Dust removal ensures a clean surface, ultimately forming a 3D effect with highly unified visual and tactile qualities.

•Translation Note: "Engrave" is an active verb suitable for the mechanical process described.

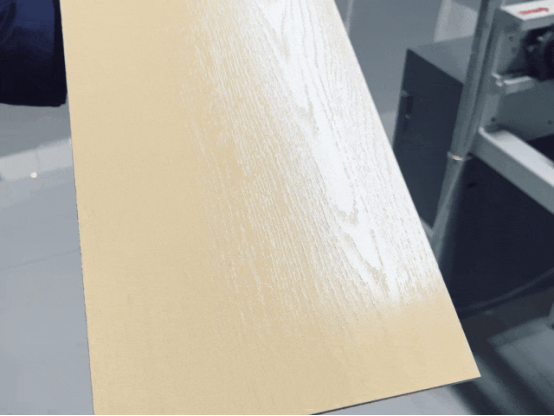

6.Matte / Gloss Topcoat Treatment

•Description: Based on the final performance and aesthetic requirements, different topcoat treatments such as matte or gloss are applied. This step not only further enhances wear and stain resistance but also gives the three-dimensional texture more tactile quality, resulting in a more realistic and aesthetically pleasing effect.

•Translation Note: "Tactile quality" translates "质感" effectively here.

Application Areas:

The Digital 3D-UV Coating Solution can be applied in two main areas: high-end panels for home decoration and custom furniture, and new types of flooring materials. It brings fresh inspiration and imagination to living spaces.

Closing Statement:

Banfert's Digital 3D-UV Coating Solution represents a profound synergy between technology and aesthetics. With its exceptional performance and limitless design potential, it is redefining the standards for floors and other surface decoration materials, charting a new course for the industry towards global markets—a path leading to high quality, high efficiency, and high customization.