Jun 30,2025

0

Record of Banfert's Safety Production Month Series of Activities

Build a solid security line to safeguard high-quality development

June 2025 is the 24th National "Safe Production Month", with the theme of "Everyone talks about safety, everyone knows how to respond to emergencies - find safety hazards around you."

Banfert actively responded to the national call and thoroughly implemented the important instructions of General Secretary Xi Jinping on work safety. It carried out a series of work safety activities with diverse forms and solid content around the theme, including more than 10 activities such as special training, emergency drills, knowledge competitions, and safety education, to comprehensively improve the safety literacy of employees and lay a solid safety foundation for the high-quality development of the company.

♦ Special training on production safety

Theory builds foundation, practice empowers

Banfert regards safety training as the "first lesson" of Safety Production Month.

01 Safety Production Month Launch Ceremony and Theme Training Session

On June 5, the head of the company's EHS Management Department conducted special training on production, storage, transportation and traffic safety, and taught an open safety production class for all employees with a clear theme, profound content and strong warning. More than 200 people participated in the open safety production class.

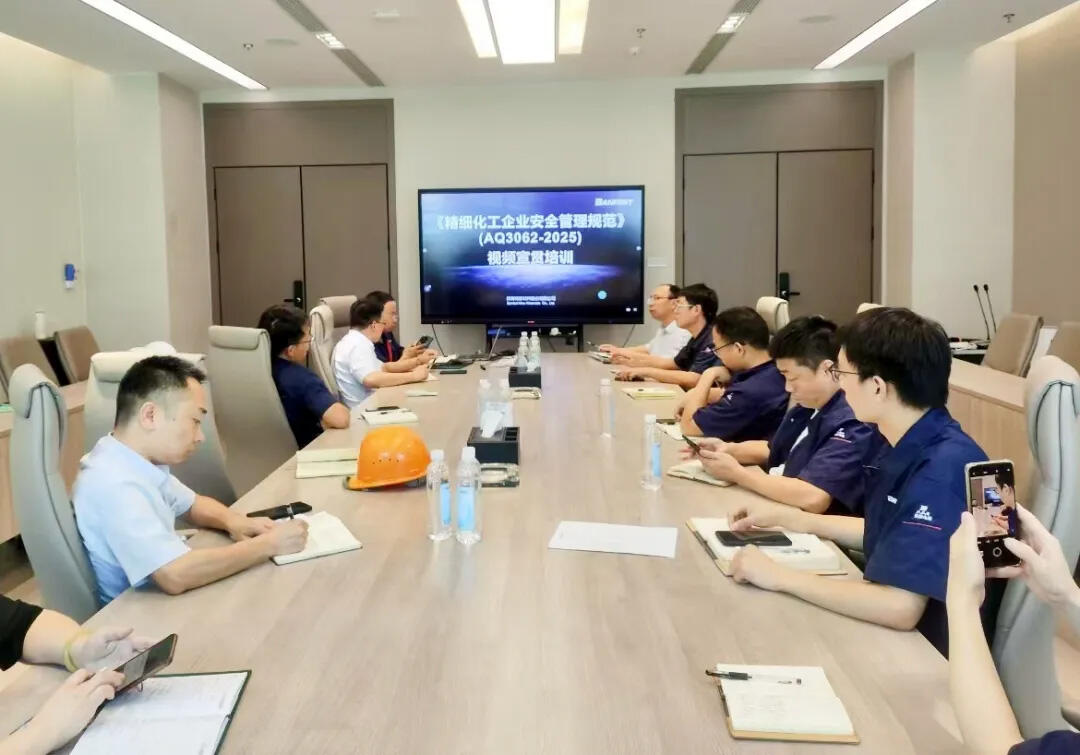

02 Special meeting on production safety

The main person in charge of Banfert presided over a relevant production safety work meeting, deeply learned the lessons of recent accidents, warned everyone to improve their ideological awareness, and focused on the theme of risk prevention and safety protection. With a high position and deep understanding, we will do a good job in production safety work, tighten and consolidate responsibilities, strengthen responsibility, strictly and conscientiously study and implement relevant safety management standards and requirements, and comprehensively promote the activities of the production safety month.

03 Production workshop safety training

In order to fully implement the main responsibility for production safety and carry out the "Safety Production Month" activities in a solid manner, all departments actively carried out departmental activities, and the production workshop carried out safety management training to teach employees how to accurately identify the "inconspicuous" but "fatal" safety hazards around them (such as equipment abnormalities, operating violations, environmental risks, etc.).

04 Double Control Mechanism Presentation

In mid-June, the company further went into workshops and offices to conduct presentations on "finding safety hazards around you" to strengthen employees' risk identification capabilities and promote the safety concept to "enter their minds and hearts". Employees said: "I used to think that hidden dangers were far away from me, but now I have learned to proactively discover and report them in a timely manner, and I feel safer."

♦ Safety Education Activities

Moisturizing silently, long-lasting infiltration

Banfert integrates safety education into daily life. Through pre-shift meetings, it organizes employees to watch a series of safety education videos such as "Life is More Important than Mount Tai", and analyzes the serious consequences of "three violations" operations with real cases.

At the same time, the EHS Management Department distributes legal safety materials such as the "Safety Production Law" and "Safety Knowledge Manual" to all employees, so that employees can check and study at any time. A workshop team leader shared: "5 minutes of safety education every day is like a 'brain wake-up call', reminding us to always tighten the safety string."

♦ Safety production knowledge competition

Promote learning through competition and inspire participation of all employees

On June 15, Banfert held a safety production knowledge competition for all employees, through the three-level competition system of "preliminary written test - semi-final selection - on-site final".

After the preliminary and semi-final written test selection, 10 contestants entered the final stage. In the final, the 10 contestants were divided into two groups. After a fierce competition of quick-answer questions and compulsory questions, the second group won the first prize with solid knowledge reserves and quick response ability.

The competition topics covered production safety regulations, emergency response procedures, hazard identification, chemical safety, etc. The atmosphere was lively and the audience interacted enthusiastically during the audience interaction stage. One contestant said with emotion: "The competition not only tests the learning results, but also makes us realize that safety is no small matter and responsibility is heavier than a mountain."

♦ Fire emergency drill

Full-scenario coverage, practical training

In order to test the feasibility of the emergency plan, Banfert carried out multi-scenario and hierarchical fire emergency drills.

First, the EHS Management Department organized various departments to conduct fire emergency desktop drills. The desktop drills included emergency working groups such as the command group, fire fighting and rescue group, communication and liaison group, warning and evacuation group, medical rescue group, and material transfer group.

At 4:00 p.m. on June 20, when the on-site alarm sounded urgently, the fire emergency drill officially kicked off. This drill simulated covering two areas: the testing building and the production workshop.

In the production workshop, after the on-site personnel discovered the fire, they immediately carried out the "report-extinguish-evacuate" action simultaneously. While reporting the dangerous situation, they used the nearest fire extinguisher to carry out the initial fire extinguishing, and the injured received timely assistance. In the inspection building area, the office staff evacuated in an orderly manner, and with the tacit cooperation of all staff, all personnel were safely evacuated to the assembly point.

After the drill, the main person in charge of Banfert conducted training on fire prevention, initial fire fighting, evacuation and escape techniques, and the use of fire extinguishers, and prepared various types of fire extinguishers for all employees to practice fire fighting, so that everyone could have a deep understanding of the hazards of fire and master basic firefighting knowledge and emergency skills.

♦ Firefighting Competition of Warehousing and Logistics Department

Practical combat training, competition to promote safety

In order to further strengthen the fire safety awareness in the warehousing and logistics links and comprehensively improve the employees' emergency response and collaborative combat capabilities in the face of sudden fires, the Banfert Warehousing and Logistics Department recently successfully held an intense and actual firefighting skills competition.

The competition was held in the form of a team, with nine key employees from the front line of warehousing and logistics forming three elite teams to compete on the same stage. The competition strictly simulated the real fire rescue environment and set up five core practical subjects: quickly and accurately putting on personal protective equipment, skillfully wearing positive pressure air respirators, efficiently connecting fire hoses, accurately implementing water gun spraying to extinguish fires, and quickly rescuing on-site materials.

The team members conducted the fire drill nervously but methodically. Their operations were skillful and standard. The whistling sound of the water impact was intertwined with the team members' steps, and the whistling sound of the water impact was intertwined with the team members' commands.

After a fierce competition, the head of the warehousing and logistics department and the head of the EHS management department gave a detailed and in-depth review of the entire competition. In the end, based on strict standards such as comprehensive time, operational standardization and task completion quality, the judges awarded first, second and third prizes on the spot to commend them for their outstanding ability and responsibility in protecting the company's safety line.

♦ Workshop anti-heatstroke drill

Prepare for a rainy day and protect your health

In view of the high-temperature operation risk areas in summer, the production workshop carried out special drills to prevent heat stroke. The drill simulated the scene of employees fainting due to heat stroke. The participants quickly activated the emergency plan, implemented measures such as cooling and rehydration, transfer and treatment, and contacted medical rescue at the same time. After the drill, the company also distributed heatstroke prevention and cooling materials and optimized the scheduling system during high-temperature periods, reflecting the high attention paid to employee health.

Conclusion

Every focused training lecture, every careful hidden danger inspection, every standardized emergency drill, and every review of safety materials have gathered into a solid force for Banfert's safety culture. We are well aware that safety is not a slogan, but an action that is integrated into daily life; emergency response is not empty talk, but a skilled instinct at critical moments.

Banfert will continue to deepen the construction of the double safety prevention mechanism and transform the results of the activities into the standards and habits of daily management. Let every employee become a "whistleblower" for safety and a "vanguard" for emergency response, jointly protect life, health and safety, and build the most solid safety foundation for the company's high-quality development!