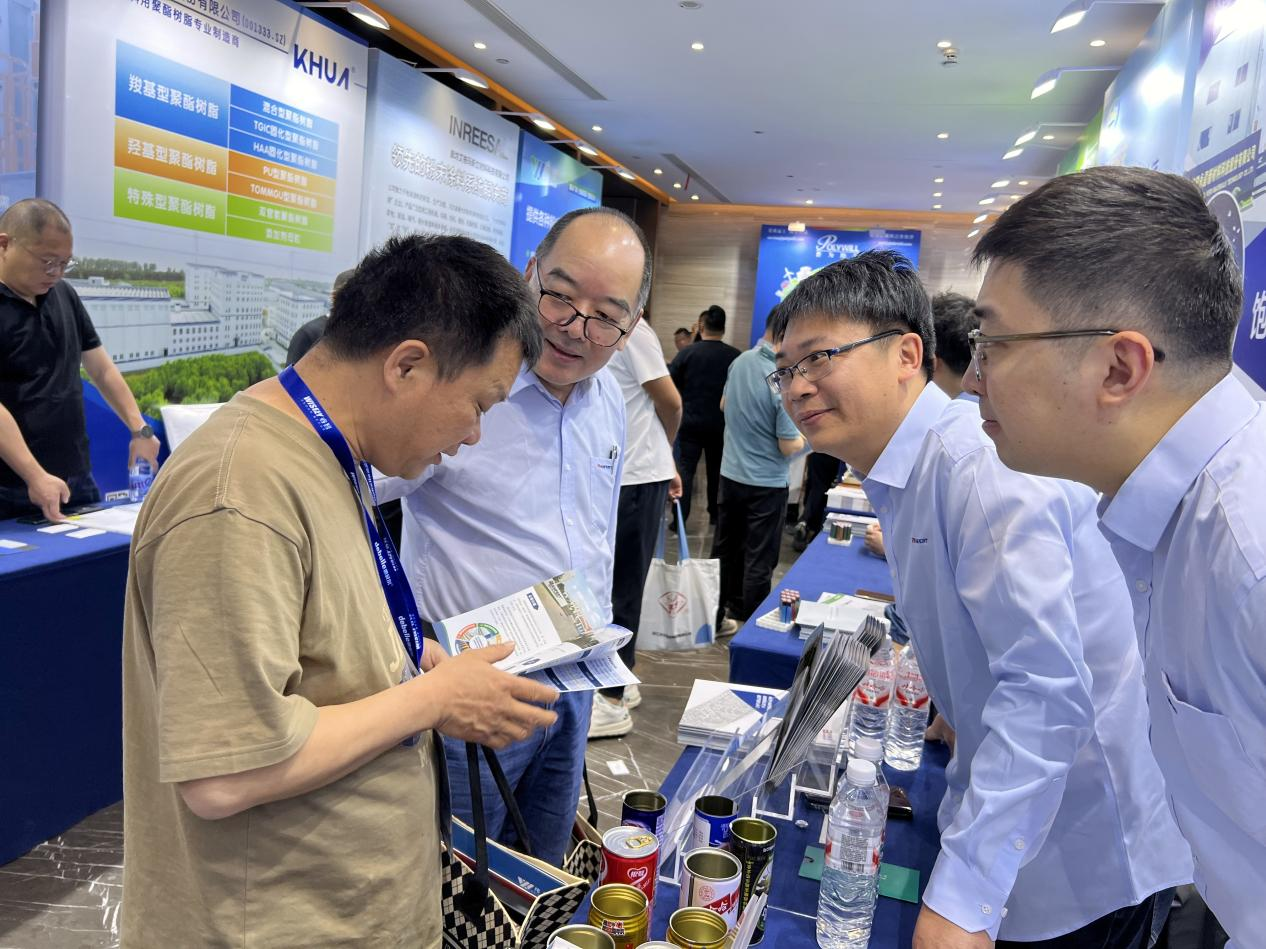

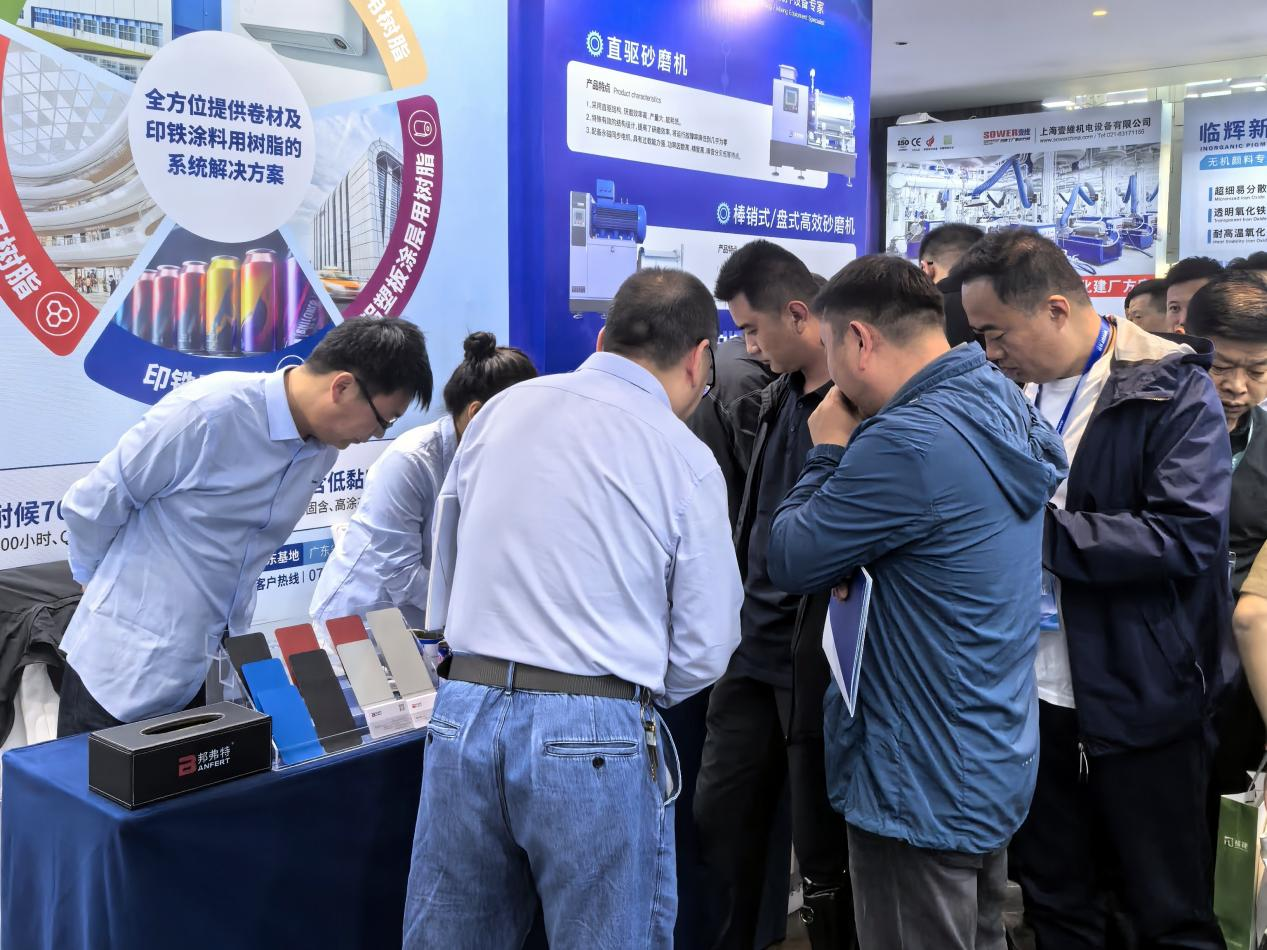

During an interview with the Coating Procurement Network, Li Xinxiong, Chairman of Banfert, elaborated on the profound significance of the green transformation of color coated sheet coatings from both the industry and enterprise levels, and shared Banfert's practices and explorations in developing high-performance and environmentally friendly resins.

He stated that, on the one hand, Banfert focuses on products with better performance. For example, it has developed high-weather-resistant resins for building materials that can withstand a 3000-hour Q-SUN test, as well as acid and alkali-resistant resins for home appliance panels. On the other hand, it makes efforts to promote UV/EB light curing technology. Through collaborative innovation among equipment manufacturers, material suppliers, and customers, it drives the entire industrial chain towards green transformation and development. Looking ahead, Banfert will continue to be committed to promoting the research and development of high-performance green resins for coatings, so as to effectively transform social and environmental values into economic values.

Innovation in UV/EB Curing Technology, Staying at the Forefront of Sustainable Development

At the present stage, the coating process of color coated sheets in China mainly relies on solvent-based coatings that release VOCs. This results in approximately 400,000 tons of VOCs being burned or emitted into the atmosphere during the production process of China's color coating industry every year. To address these issues, the entire industrial chain needs to achieve green and sustainable development of color coated sheet coating through technological innovation.

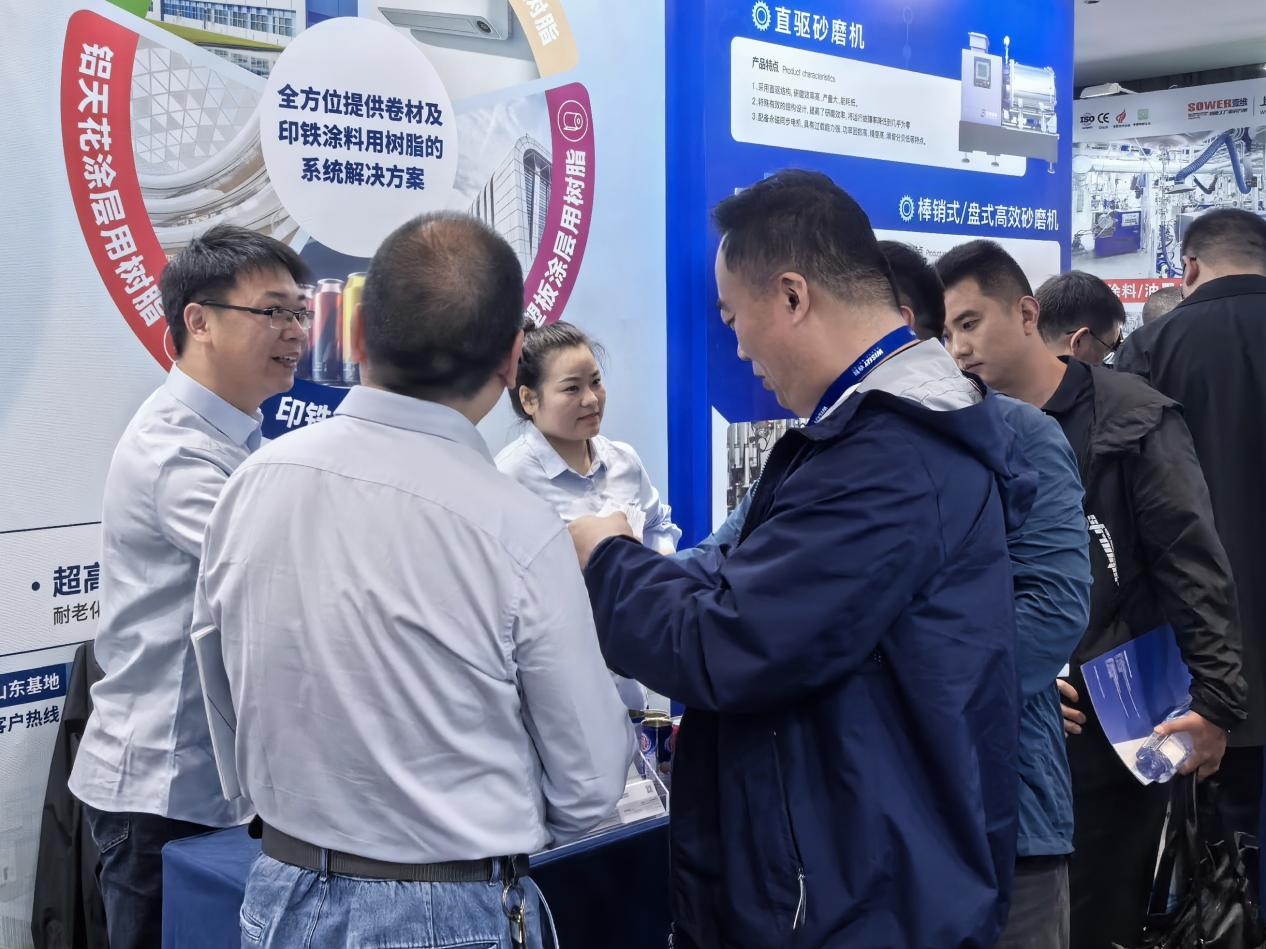

During the afternoon speech session, Sun Liyan, Director of Product R&D for Basic Materials at Banfert, delivered a speech themed "The Road to Sustainable Development of Ultra-high Weather-resistant Resins and UV/EB Curing Coating Technologies". Starting from the company introduction to the global layout, and from system certifications to R&D capabilities, Director Sun first introduced the "hardcore" strength of the company that supports the development of high-performance and environmentally friendly products.

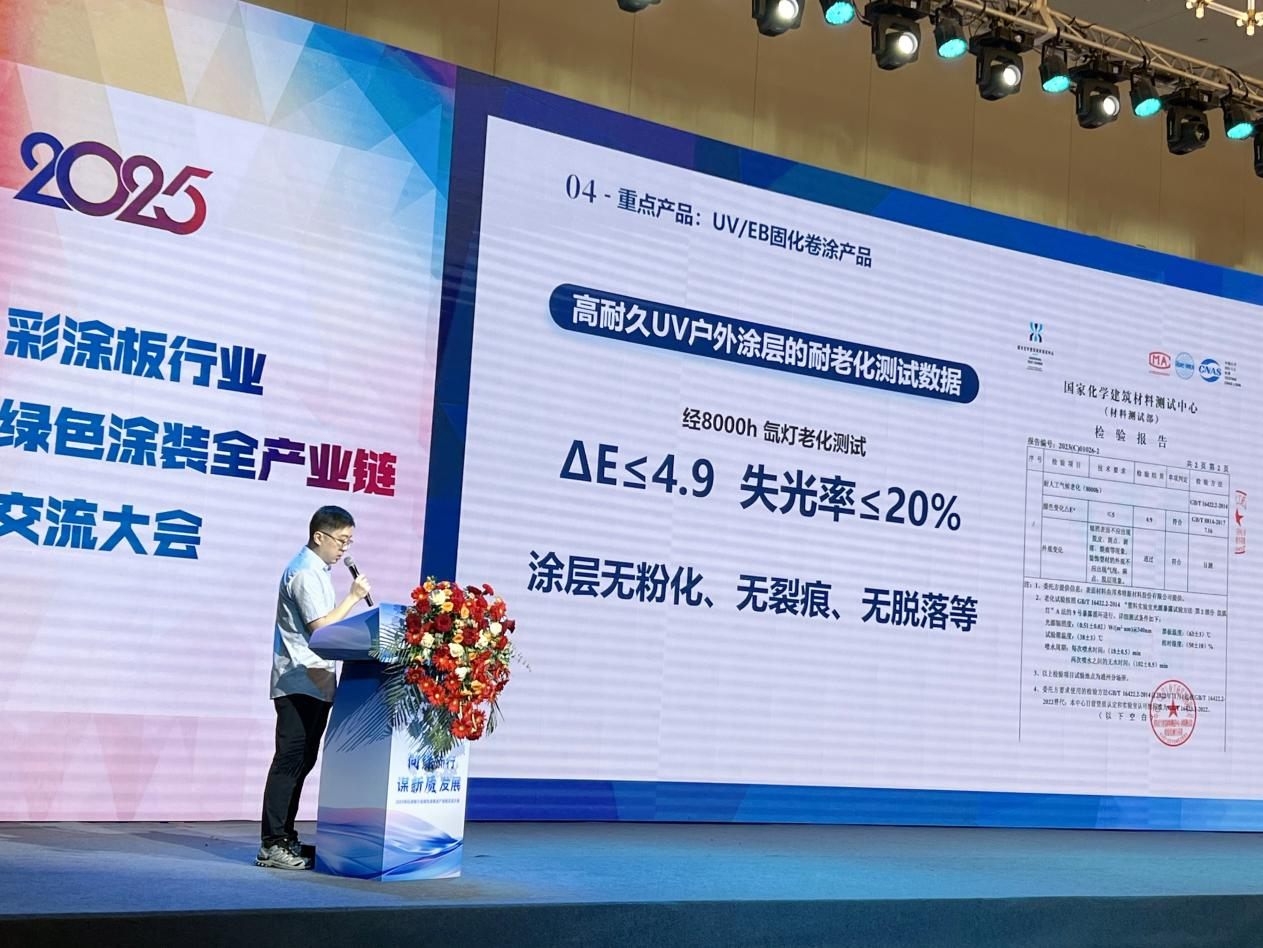

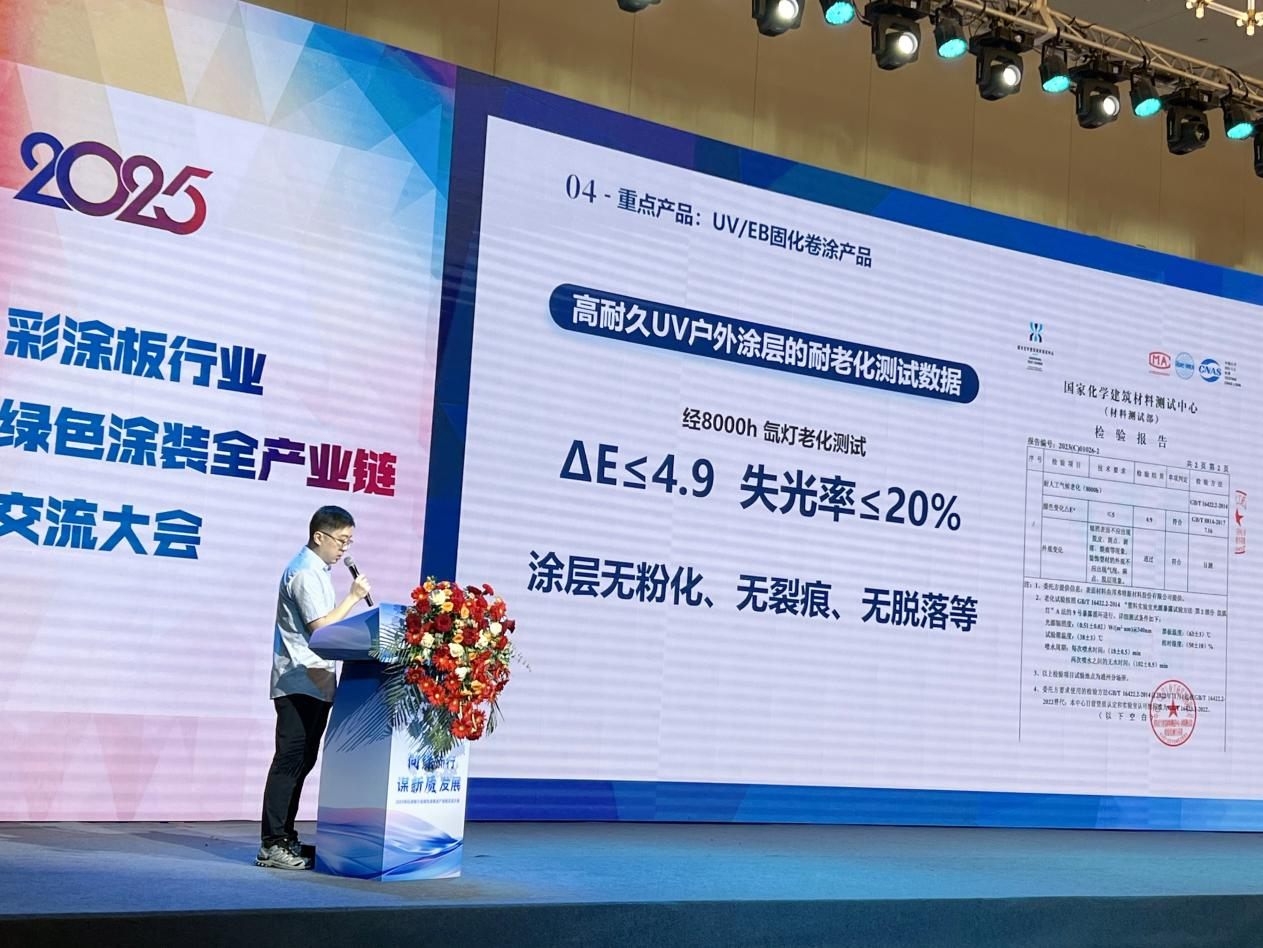

In the part of product application and development, he mainly introduced two key products: the ultra-high weather-resistant resin and the high-durability UV outdoor coating. The ultra-high weather-resistant resin 7050 has extremely strong weather resistance. After being irradiated by a xenon lamp for 3000 hours, its gloss loss rate is only 2.6%. The high-durability UV outdoor coating has undergone an 8000-hour xenon lamp aging test. The test results show that ∆E≤4.9, the gloss loss rate ≤20%, and there are no phenomena such as powdering, cracking, or peeling of the coating.

It is particularly worth mentioning that the UV/EB cured coil coating products have broken through the original hot melt curing technology and achieved innovation in ultraviolet light or electron beam curing technology. This technological innovation is also more in line with the market innovation needs in the context of the dual-carbon goals, promoting the efficient and sustainable development of the coating industry for color coated sheets, and at the same time, working together with the entire industrial chain to achieve a comprehensive breakthrough.

Standing at the turning point of the coating of color coated sheets, only by deeply integrating technological innovation with industry needs can the technical value of coatings be transformed into practical value and become the core driving force for the development of the industry and even society. Banfert will continue to use efficient, environmentally friendly, and high-performance product solutions to promote the simultaneous leap in performance and environmental protection of the coating of color coated sheets.